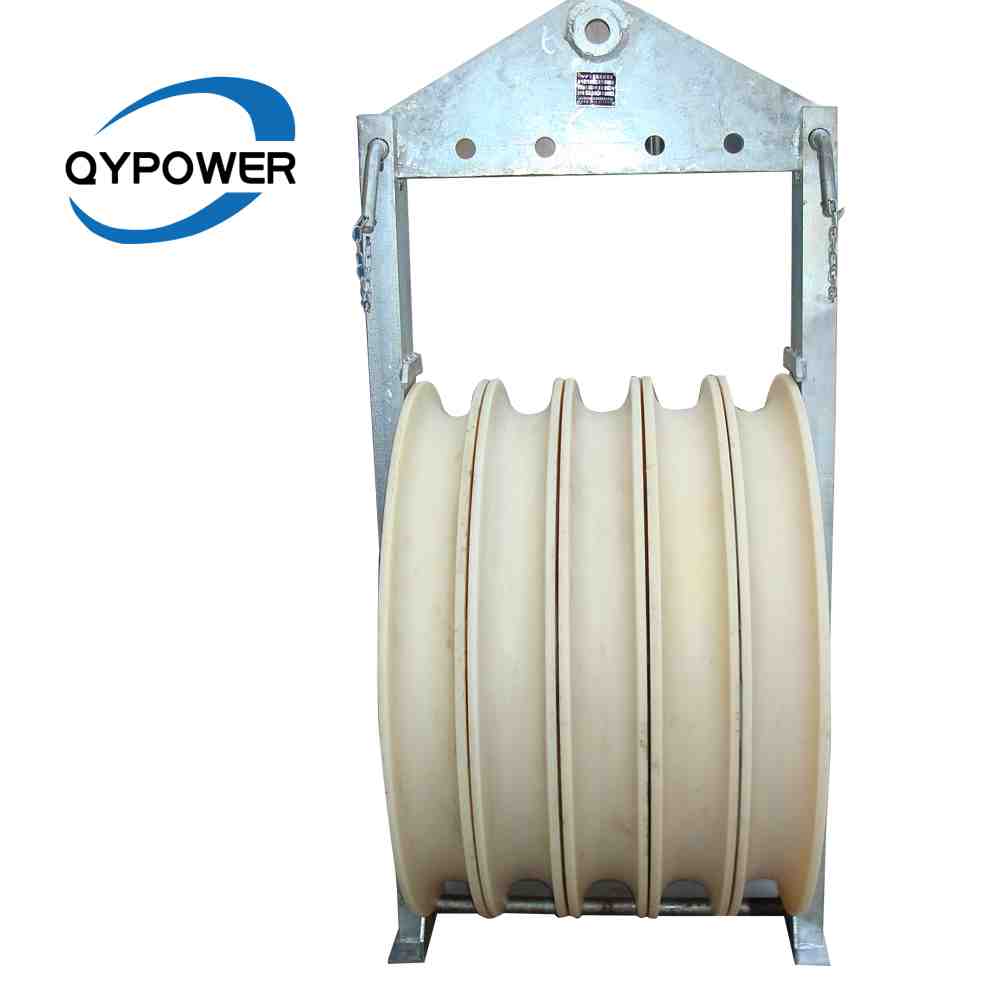

Large Diameter MC Nylon Stringing Blocks

Scope of application: these Large Diameter MC Nylon Stringing blocks are used to release the wire and conductor in the overhead transmission line project.

Brand: QYPOWER

Payment Type: T/T, L/C

Incoterm: FCA, FOB, CFR, CIF

MOQ: 5PCs

Productivity: 500PCS per month

Transportation: Ocean, Land, Air

Packaging: Plastic Bag or Steel Frame

Place of Origin: CHINA

Certificate: By China High Voltage Institute.

Delivery Time: 5-10 days

Warranty: 1 year since the B/L date

Product Status: In stock for 100pcs each type, max 3-4 weeks required if for more mass production.

View More Stringing Blocks or Rollers From QYPOWERLINE

Large Diameter Mc Nylon Stringing Blocks

Technical Parameters:

1. What is Stringing Blocks

Definition and Purpose

Stringing blocks, also known as conductor blocks or sheaves, are specialized devices designed to guide and support conductors during the installation process. These blocks are essential for minimizing friction and preventing damage to the conductors, ultimately contributing to the efficiency and safety of power line construction projects.

Importance in Power Line Construction

In power line construction, stringing blocks play a pivotal role in ensuring that conductors are installed without twists or damage. They facilitate smooth conductor movement, reduce tension, and enhance overall operational safety.

2. Types of Stringing Blocks

Single Sheave Blocks

Single sheave blocks are designed for straightforward applications involving single conductors. They are lightweight and easy to handle, making them ideal for less complex projects.

Multiple Sheave Blocks

Multiple sheave blocks are equipped with multiple wheels to accommodate bundled conductors. They are essential for projects involving multiple conductors, ensuring synchronized movement and reducing the risk of entanglement.

Helicopter Stringing Blocks

Helicopter stringing blocks are specifically designed for aerial installations. They are lightweight and durable, facilitating efficient conductor placement in challenging terrains.

Grounded Stringing Blocks

Grounded stringing blocks are equipped with grounding mechanisms to prevent electrical hazards during installation. They are crucial for ensuring worker safety in live-line conditions.

3. Applications of Stringing Blocks

Power Transmission Lines

Stringing blocks are indispensable in the installation of power transmission lines, ensuring that conductors are laid out efficiently and safely.

Telecommunications

In the telecommunications industry, stringing blocks facilitate the installation of fiber optic cables, ensuring minimal signal loss and structural integrity.

Construction and Engineering Projects

Beyond power and telecommunications, stringing blocks are utilized in various construction and engineering projects that require the precise installation of cables and wires.

4. Advantages of High-Strength Nylon Stringing Blocks

Lightweight and Durable

High-strength nylon stringing blocks are significantly lighter than their metal counterparts, reducing the physical strain on workers and equipment. Despite their lightweight nature, they offer exceptional durability and wear resistance.

Enhanced Safety Features

Nylon blocks do not produce friction sparks, enhancing safety during operations. Their design also minimizes the risk of conductor damage, ensuring a secure installation process.

Self-Lubricating Properties

The self-lubricating nature of nylon reduces friction between the conductor and the block, facilitating smoother operations and extending the lifespan of both the conductor and the block.

Resistance to Environmental Factors

Nylon stringing blocks are resistant to corrosion and can withstand harsh environmental conditions, making them suitable for outdoor operations.

5. QYPOWER: Leading Manufacturer of Stringing Blocks

Company Overview

QYPOWER is a renowned manufacturer and supplier of stringing blocks and other power line construction tools. With years of experience, the company has established itself as a leader in the industry, delivering high-quality products to clients worldwide.

Commitment to Quality and Innovation

QYPOWER is dedicated to continuous improvement and innovation, ensuring that their products meet the evolving needs of the industry. Their stringing blocks are designed with the latest technology to provide superior performance and reliability.

Customization Services

Understanding that each project has unique requirements, QYPOWER offers customization services to tailor stringing blocks to specific needs, including size, material, and design specifications. Compared with other manufacturer, we especially customize for your solution.

6. Manufacturing Process of Stringing Blocks

Material Selection

QYPOWER selects high-quality materials, such as reinforced MC nylon and galvanized steel, to ensure the durability and performance of their stringing blocks.

Production Techniques

Utilizing advanced manufacturing techniques, QYPOWER produces stringing blocks that meet stringent quality standards. Their production process includes precision molding and assembly to ensure consistency and reliability.

Quality Control Measures

Each stringing block undergoes rigorous testing to verify its strength, durability, and performance. QYPOWER’s commitment to quality ensures that their products meet or exceed industry standards.

7. How to Use Stringing Blocks Effectively

Installation Guidelines

- Proper Placement: Ensure that stringing blocks are securely attached to the supporting structures to prevent movement during operations.

- Alignment: Align the blocks correctly with the intended path of the conductor to facilitate smooth movement.

Maintenance Tips

- Regular Inspections: Conduct routine checks for wear and tear, and replace any damaged components promptly.

- Cleaning: Keep the blocks clean from debris to maintain optimal performance.

Safety Precautions

- Training: Ensure that all personnel are trained in the proper use and handling of stringing blocks.

8. Key Considerations for International Buyers

When sourcing stringing blocks from a supplier, especially from overseas, there are several key factors that international buyers should consider to ensure they’re getting a high-quality product at a fair price. Here are some crucial questions to ask and points to consider:

Questions to Ask Suppliers

- Material Specifications: What materials are used in manufacturing? Are they high-strength, durable, and suitable for your specific environmental conditions?

- Customization Options: Can the supplier customize stringing blocks to your unique requirements, including variations in size, material, or additional safety features?

- Quality Assurance: What quality control processes are in place? Does the supplier conduct rigorous testing to ensure durability, safety, and efficiency?

- Certifications and Standards: Does the product meet industry standards and certifications, such as ISO certifications or other relevant standards?

- Lead Time and Delivery: What is the typical lead time for production and delivery, especially for large or custom orders?

Understanding Pricing and Cost Factors

The pricing of stringing blocks can vary depending on factors such as material quality, level of customization, and order volume. Here are some cost considerations:

- Material Costs: Premium materials like reinforced MC nylon and galvanized steel may cost more, but they offer long-term durability.

- Customization Fees: Custom designs, sizes, and features may increase costs slightly but offer better alignment with specific project needs.

- Bulk Discounts: Many suppliers, including QYPOWER, offer discounts for bulk orders, which can reduce per-unit costs for larger projects.

Shipping and Delivery Information

International buyers should also inquire about shipping options, estimated delivery times, and any additional fees related to international logistics. Reliable suppliers like QYPOWER provide efficient packaging on steel reels or wooden drums, ensuring that the stringing blocks arrive safely and ready for immediate use.

9. Frequently Asked Questions (FAQs)

To assist buyers in understanding the essential aspects of stringing blocks, here are answers to some common questions:

- What materials are used in QYPOWER’s stringing blocks?QYPOWER’s stringing blocks are crafted from high-strength MC nylon, known for its lightweight durability, and galvanized steel, which offers excellent corrosion resistance.

- Can stringing blocks be customized for specific projects?Yes, QYPOWER offers extensive customization options. Clients can specify parameters such as size, material, and even additional safety features to meet project requirements.

- How do I determine the right type of stringing block for my needs?The right type depends on factors like conductor type, tension requirements, and environmental conditions. QYPOWER’s team can guide you through the selection process to ensure optimal performance.

- What is the typical lead time for orders?Lead times can vary depending on order size and customization needs. Small orders usually take 10-15 days, while larger or highly customized orders may require up to 30-90 days. Contact QYPOWER for specific timelines.

- How does QYPOWER ensure product quality?QYPOWER employs stringent quality control measures, including durability testing and inspections, to ensure each stringing block meets high industry standards. The company works closely with institutes to verify product performance and safety.

- Are bulk order discounts available?

Yes, QYPOWER offers competitive pricing and discounts for bulk orders, helping customers save on larger projects.