Best Anti Twisting Steel Wire Rope for pulling OPGW, ADSS cable, and bundled conductors

Scope of application: Galvanized Anti Twisting Steel Wire Rope is specially used for pulling OPGW cables and conductors in power line transmission project.

Brand: QYPOWER

Payment Type: T/T, L/C

Incoterm: FCA, FOB, CFR, CIF

MOQ: 1KM

Productivity: 200KM per month

Transportation: Ocean, Train, Air

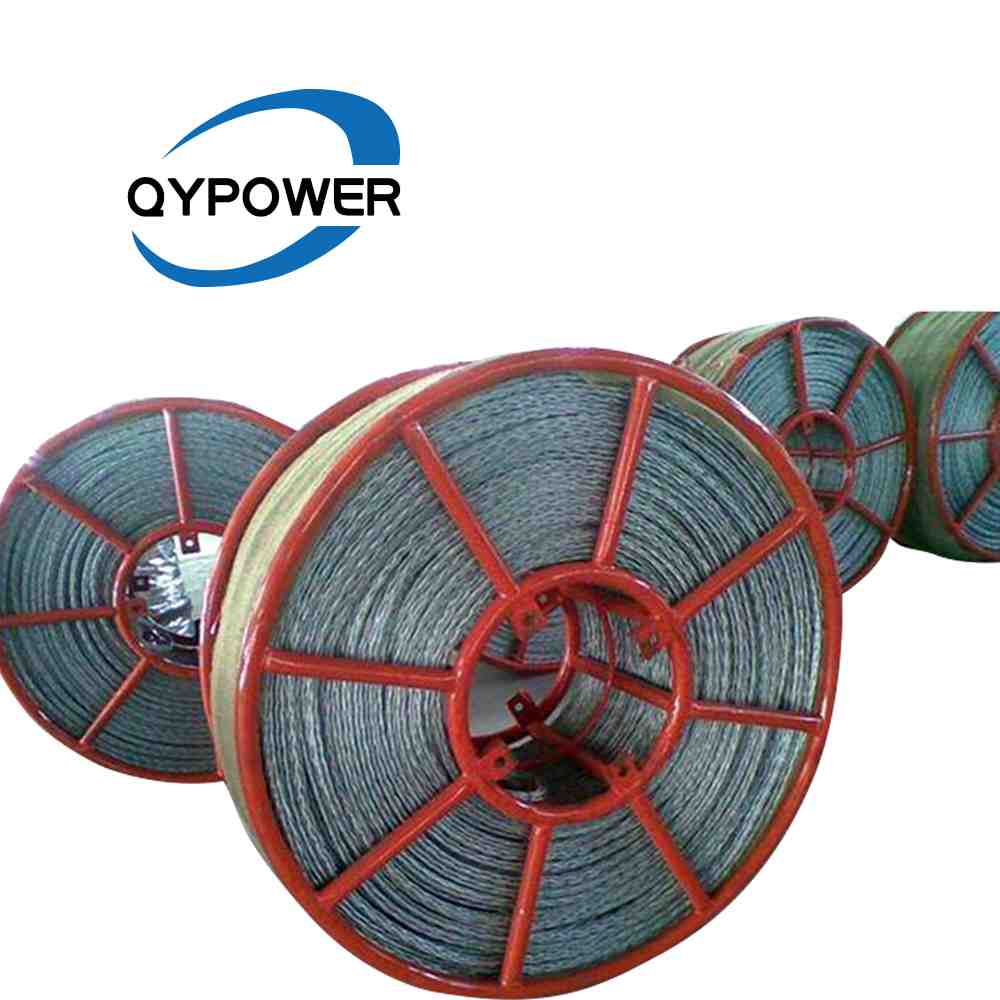

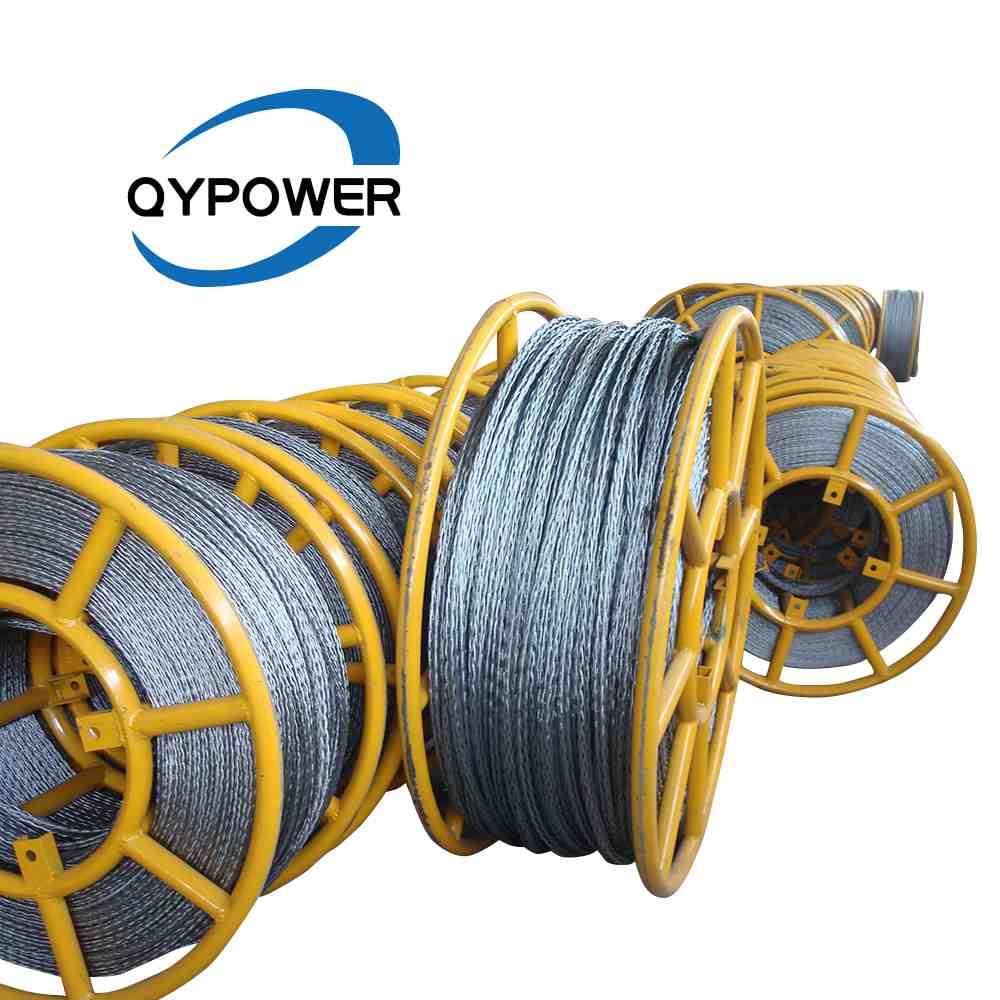

Packaging: Standard Steel Reel

Place of Origin: CHINA

Certificate: By China High Voltage Institute.

Delivery Time: 5-10 days

Product Status: In stock for 10KM each type, max 8 weeks required if for more mass production.

View More Anti Twist Wire Rope From QYPOWER.

QYPOWER‘s anti twisting steel wire rope is a special braided steel wire rope made of high-strength hot-dip galvanized high-quality aviation steel wire processed by special technology. After hot-dip galvanizing, it has excellent oxidation and corrosion resistance performance, this rope is woven from galvanized steel wire ropes (1 * 19W, 1 * 25Fi, and 1 * 29Fi). This special anti twisting steel wire rope is widely used in power line stringing operations, for pulling conductors, OPGW cable, ADSS, 500kv traction rope, etc.

QYPOWER, a leading manufacturer and supplier in China, has earned a reputation for producing high-quality anti-twisting steel wire ropes that meet the exacting standards of clients worldwide. With a commitment to quality, customer satisfaction, and efficiency, QYPOWER delivers solutions that stand the test of time and harsh operating conditions. In industries where safety, precision, and durability are paramount, anti-twisting steel wire ropes have become indispensable. Designed to prevent rotation under load, these ropes provide unmatched stability and reliability across various sectors, including power line stringing, construction, marine, and mining.

Technical Parameters:

Product Brief Description:

1.The models are divided into 4-sided 8-strand, 4-sided 12 trand, and 6-sided 12 trand.

2. Currently, the main ones used are 6-sided 12 trands, with diameters ranging from 9mm to 30mm for customers to choose from.

3. The length with a diameter of 9-20mm is generally 1000 meters per reel; For sizes greater than 20mm, the standard length is 800 meters per reel.

4. When subjected to tension in a free state, the rotation angle of the steel wire is 0, and the composite torque is 0.

5. The rope has good flexibility and does not knot, entangle, break or hook after releasing tension.

6. The anti twisting steel wire rope with 6 sides and 12 strands is more suitable for use with hydraulic pullers and tensioners, engine powered winch, cranes, and other more equipment.

What is Anti-Twisting Steel Wire Rope?

Definition and Unique Properties

Due to its square or hexagonal cross-section, it does not twist when subjected to force, also known as square non rotating steel wire rope. Compared with ordinary round stranded steel wire rope, it has the advantages of high strength, good flexibility, anti-corrosion and rust prevention, no need for gold hooks, less likely to knot, and long service life. Suitable for power line transmission construction, balanced tail ropes for vertical shaft lifting equipment, and places where steel wire ropes are required to not rotate during high lifting such as mines and docks.

In order to solve the problem of twisting and breaking of ordinary twisted steel wire ropes and twisted braided multi-layer (non rotating) steel wire ropes, our company has developed and produced a series of fully anti twist special steel wire ropes based on imported braided steel wire from Italy. The characteristic of this rope is to use four strands, six strands, and eight strands to twist alternately on the right, and weave them into squares and hexagons according to certain rules with the same number of strands.

The anti twisting steel wire rope woven into it has equal left and right alternating twisting on the cross section. Regardless of whether it is under force or not, the twisting force on the cross section can cancel each other out, so the total twisting torque of the steel wire rope is zero, that is, it does not rotate. This type of anti twisting steel wire rope also has the characteristics of good flexibility and corrosion resistance.

How Anti-Twisting Steel Wire Rope Differs from Standard Steel Ropes

Unlike standard steel ropes, which tend to rotate and twist under load, anti-twisting steel ropes maintain their stability, making them safer and more effective for specific applications. The anti-twisting feature enhances not only safety but also efficiency, as it reduces the likelihood of tangling, equipment damage, and accidents during operations.

Key Benefits for Potential Customers

Solving Common Problems and Pain Points

- Twisting and Tangling Issues: One of the most common challenges in using traditional steel ropes is their tendency to twist and tangle, leading to operational delays, safety risks, and potential damage to equipment. Anti-twisting steel ropes effectively solve this problem by maintaining a stable structure under load.

- High Maintenance and Replacement Costs: Standard ropes often require frequent maintenance or replacement, increasing overall project costs. Anti-twisting steel wire ropes, with their specific character and durability and long lifespan, help reduce these expenses significantly.

- Operational Inefficiency: For projects requiring precise load positioning, anti-twisting steel wire ropes minimize manual adjustments, improving operational efficiency and reducing labor costs.

Addressing Customer Needs and Aspirations

- Reliability in Harsh Conditions: Customers working in industries like power line construction, mining, and marine need products that withstand tough environments. Anti-twisting steel wire ropes are engineered for resilience, providing peace of mind in even the most demanding applications.

- Long-Lasting Performance: These ropes deliver consistent performance over extended periods, allowing customers to achieve uninterrupted operations and reduced downtime.

- Cost-Effectiveness: With fewer replacements and repairs, customers experience a reduction in long-term costs, enabling them to allocate resources more effectively.

Why Choose QYPOWER Over Competitors?

- Quality Assurance: QYPOWER’s stringent quality control measures ensure every rope meets the highest standards of durability and performance.

- Customization Options: Unlike many competitors, QYPOWER offers tailored solutions to meet specific client requirements, from diameter, length and tensile strength to strand configuration.

- Competitive Pricing and Value: Despite their high quality, QYPOWER’s anti-twisting steel ropes are competitively priced, normally 20% lower price than competitor, thus providing customers with excellent value.

- Exceptional Customer Service: QYPOWER prioritizes customer satisfaction, offering responsive support, after-sales service, and timely delivery, which further sets it apart from competitors.

Applications of Anti-Twisting Steel Wire Rope

Power Line Stringing

Anti-twisting steel wire ropes are essential in power line stringing for pulling conductors, OPGW (Optical Ground Wire), and ADSS (All-Dielectric Self-Supporting) cables. The rope’s stability prevents rotation, which is critical for maintaining the integrity of power lines. QYPOWER’s ropes are designed to meet the demands of high-voltage transmission projects, ensuring efficient, safe, and reliable installations.

Construction and Engineering

In construction and engineering, anti-twisting steel ropes are used for tasks like hoisting and lifting. Their ability to resist rotation ensures that loads remain stable, reducing the risk of accidents and improving precision in material handling. This is particularly important in high-rise construction projects where precision and safety are paramount.

Marine and Offshore Applications

Marine and offshore applications demand ropes that can withstand corrosion and harsh environmental conditions. Anti-twisting steel ropes made from galvanized steel offer excellent resistance to saltwater corrosion, making them ideal for mooring, towing, and lifting in maritime environments. Their stability under load also ensures smooth operations, reducing the risk of entanglement.

Mining and Heavy Industries

In mining and heavy industries, the strength and durability of anti-twisting steel ropes are vital. These ropes are used for material extraction, transport, and heavy lifting. The non-rotating property prevents twisting that could otherwise cause safety hazards in the demanding conditions of mining operations.

Types and Specifications of Anti-Twisting Steel Wire Rope

Different Strand Structures

- 4 sides 8-Strand Braided: This structure provides a balance between strength and flexibility, making it suitable for general industrial applications.

- 6 sides 12-Strand Braided: Known for enhanced flexibility, this structure is ideal for complex rigging and precision work where stability is crucial.

Various Diameters and Tensile Strengths

QYPOWER offers anti-twisting steel wire ropes in a range of diameters, typically from 9mm to 30mm, and tensile strengths from 1960 MPa to 2160 MPa. This versatility allows customers to select ropes based on specific load requirements, ensuring optimal performance in various applications.

Customization Options

With its extensive customization services, compared with other suppliers, QYPOWER can tailor anti-twisting steel wire ropes to meet unique client requirements. Customization options include:

- Length: Choose the ideal rope length for your application. Normally 800m and 1000m/reel

- Strand Structure: Select from a variety of strand configurations, 8 and 12 strands

- Tensile Strength: Pick the appropriate tensile strength for your load needs.

- Forms: different forms of rope, 4 forms and 6 forms, always 6 forms is more preferred for most projects.

Manufacturing Process of Anti-Twisting Steel Wire Rope

Material Selection and Sourcing

QYPOWER prioritizes quality from the outset by selecting high-grade galvanized steel, known for its corrosion resistance and strength. This ensures that each rope can withstand rigorous conditions while maintaining its structural integrity.

Braiding and Twisting Techniques

Using advanced braiding machines, QYPOWER intertwines steel wires into the desired strand structure, which counteracts rotational forces. This intricate process is critical to achieving the anti-twisting properties that make these ropes reliable and effective.

Quality Control and Testing

Each anti-twisting steel wire rope undergoes stringent testing to verify its tensile strength, flexibility, and anti-twist capability. QYPOWER’s commitment to quality means that every rope meets industry standards as they are tested by China High Voltage Institute, delivering durability and safety in various operational settings. And our quality control and delivery conditions are listed as follows:

1. The anti twisting steel wire rope shall be delivered and accepted within the manufacturing length within ± 2% of the user’s required length.

2. No joints of any kinds are allowed in each strand of the rope.

3. The length of the sleeve at both ends of the rope shall not be less than 5 pitch lengths, and can also be made according to the user’s requirements.

4. The appearance of the rope should be free of jumping, wrong, disorderly, loose, or damaged strands.

5. The cross-section of the rope is square or hexagonal, with adjacent corners being strands of opposite rotation direction and diagonal corners being strands of the same rotation direction.

6. The breaking load of the rope is calculated based on the tensile strength of each strand, and users should consider the safety factor (3 times the safety factor) when selecting. However, in practical applications, the breaking load of the rope cannot be used as the working load.

Packaging and Delivery

Ropes are typically wound onto sturdy and standard steel reels or drums(usually used for hydraulic tensioner or puller), allowing for safe and efficient transportation. This packaging method ensures the ropes reach clients in pristine condition, ready for immediate deployment.

Benefits of Choosing QYPOWER’s Anti-Twisting Steel Wire Rope

High Quality and Durability

QYPOWER’s ropes are designed for longevity and consistent performance, even in extreme conditions. This reliability means reduced replacement costs and minimal operational disruptions for clients.

Enhanced Work Efficiency

The anti-twisting design minimizes downtime and enhances safety, as there is less need for manual adjustments or untangling. This efficiency translates into lower labor costs and faster project completion times.

Competitive Pricing

Despite its focus on quality, QYPOWER offers competitive pricing 20% lower than competitors, ensuring clients receive the best value for their investment. The reduced need for frequent replacements further increases cost savings.

Exceptional Customer Support and Service

QYPOWER’s customer-centric approach includes responsive support, customization options, and a commitment to timely delivery. Clients are assured of a reliable partnership that goes beyond the initial purchase.

Key Considerations When Buying Anti-Twisting Steel Wire Rope from China

Important Questions to Ask a Supplier

- Material Quality: What materials are used, and do they meet industry standards?

- Customization Options: Can the supplier adjust specifications to meet specific needs?

- Quality Assurance: What testing processes are in place?

- Certifications: Does the product have necessary certifications for export?

- Lead Time: How long is the typical delivery period for custom orders?

Understanding Pricing and Cost Factors

Pricing varies depending on material quality, customization, and order quantity. By discussing these factors with suppliers like QYPOWER, buyers can secure competitive pricing while ensuring high-quality products.

How to Use Anti-Twisting Steel Wire Rope Safely and Effectively

Installation Guidelines

Proper installation is crucial for maximizing performance. Following manufacturer guidelines for tensioning and anchoring can help prevent accidents and extend the rope’s lifespan.

Maintenance Tips for Longevity

Regular inspections, lubrication, and avoiding excessive loads can enhance durability. QYPOWER provides guidelines to ensure clients get the maximum life and performance from their ropes.

Safety Precautions

Training operators on safe usage, inspecting ropes before each use, and using the correct load capacity are essential to maintaining safety and operational integrity.

FAQs – Tips for Buyers of Anti-Twisting Steel Wire Rope

- What makes anti-twisting steel wire rope different from regular steel rope?

-

- Anti-twisting ropes resist rotation, offering stability and precision where needed.

- Can these ropes be customized?

-

- Yes, QYPOWER offers various customization options for specific requirement like package, length and diameter.

- What industries are they most commonly used in?

-

- Normally, they are used in power line transmission project, but still in construction, marine, and mining sectors.

- How to choose the right diameter and tensile strength?

-

- Consider load requirements, operating conditions, and consult with QYPOWER for guidance.

- What is the typical lead time for orders?

-

- Lead times depend on customization needs; for small QTY, 10-15 days, for larger order, 30-90 days, contact QYPOWER for specifics.

- Are there minimum order quantities?

-

- QYPOWER can accommodate different order sizes to meet client needs. Normally MOQ 1km.

- How to ensure product quality from a Chinese supplier?

-

- Work with reputable suppliers like QYPOWER, known for rigorous quality control.

- What packaging options are available?

-

- Ropes are wound on standard steel reels for hydraulic puller or hydraulic tensioner, but if for normal use, wooden reels are enough.

- What maintenance is recommended?

-

- Routine inspections and lubrication will extend the rope’s lifespan. If made from galvanized steel wire, normal dust removing is ok.

- How does anti-twisting wire rope help reduce operational costs?

-

- High strength, and rusted proof. Reduced wear and minimal maintenance result in lower long-term costs.

Our package and loading